How Dispersion Works

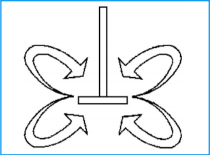

High shear dispersion works when particles contact a rotating dispersion blade and are broken apart. The process requires equipment with high RPM and HP in order for the dispersion blade to reach tip speeds of 2,500 to 5,000 feet per minute. The optimum action of a disperser is a combination of rotary and radial flow. A particle starting at the outer edge of the container should travel to the center of the vortex in less than 360 degrees.

Mixing and dispersing differ because the mixing process is simple agitation at a lower horsepower and speed whereas dispersion is an intense turbulent high shear process. Dispersers are stable pieces of industrial equipment that are not mounted to a container. INDCO offers both tabletop and floor mounted options from lab scale up to 200 gallon containers. Round containers are the best option for optimal dispersion results because they have no “dead areas” in the corners.

Learn how to get the most from your dispersion with our step-by-step infographic or download the pdf version of this post.

How Dispersion Works: Steps

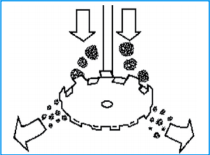

1. Dispersion blade turns

2. Particles contact the blade and are broken apart

a. The process of dispersion is a high-speed, high-shear process requiring high horsepower – in the intense turbulence surrounding the blade, particles collide at high speeds and are further broken apart.

b. To reach optimum dispersion the dispersion blades should run at tip speeds of 2,500 to 5,000 feet per minute. Your precise speed can be determined by using the following equation FPM = RPM x .262 x Blade Diameter (inches).

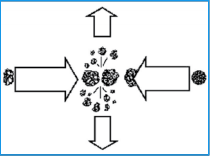

3. The flow then divides into upward and downward components at the vessel wall ensuring complete circulation.

4. Beyond the zone of attrition the now broken down material is thoroughly mixed and particles dissolved or dispersed by the horizontal laminar flow extending from the blade.