Agitators vs. Mixers: Differences and Considerations

Is there a difference? Technically speaking, an agitator is a machine with the purpose of moving liquid. The desired movement is often - but not always - intent upon achieving a uniform solution of multiple ingredients, i.e. its purpose is to mix. In the industrial world the terms agitator and mixer are used interchangeably and essentially mean the same thing. So, the short answer: No, there is effectively no difference.

Here at INDCO, rather than differentiating between “industrial mixer” or “industrial agitator,” we use the term “mixer” for all of our industrial mixing products to keep everything streamlined and easy for our customers.

Whatever you call them, the most important question to ask yourself is “Which industrial mixer is right for my application?”

Before you buy.

INDCO customer service representatives and engineers are available to help you choose the best option, but we recommend you make a few notes on what will be required or necessary to complete your process.

The most important notations will be minimum and maximum batch sizes, the overall dimensions of your desired vessel and the specific gravity or weight per gallon of the ingredients that will be used. In addition to these three key items, consider:

- Material properties.

- Initial ingredient and final product viscosities.

- Corrosive or flammable properties.

- Solubility of solids and concentration used.

- Desired process outcomes (blended liquids, solids suspension, etc.).

- Process description.

- Sequence of ingredient addition.

- Previous processes successfully used.

- Where the process will occur (indoors, outdoors, etc.).

INDCO is here to help.

By having this information on hand before you contact INDCO, our team will be better equipped to help you or your team select the right industrial mixer, impeller type and speed to ensure optimal results.

Using this helpful information, we then build a theoretical vessel and equipment design for your industrial mixer to meet the required material flow and flow pattern. At this stage, torque and horsepower are also determined.

After the impeller type, horsepower and torque to provide the desired flow pattern and agitation are defined, INDCO engineers can create a detailed mechanical design.

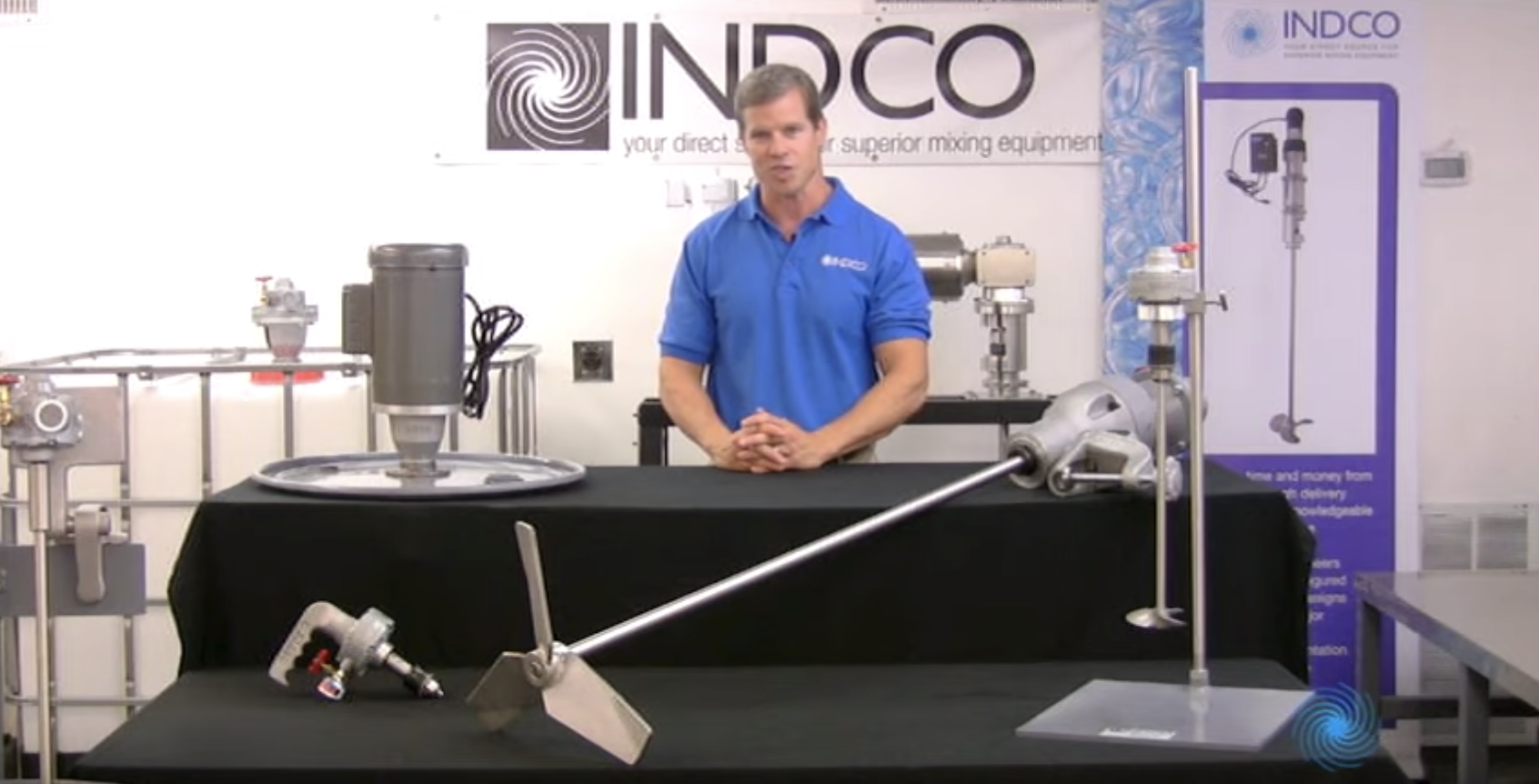

Learn more about the industrial mixers and mixing equipment INDCO has to offer by watching the video below.

Final considerations.

Engineers and operations professionals across a variety of fields have individual process requirements to meet application needs. Because of this, there are many specific variables that come into play depending on the industry for which the industrial mixer will be used.

Specifications and code requirements for equipment design vary from industry to industry, and knowing these can be critically important for maintaining compliant operational procedures. For example, 3-A and FDA specifications require stainless-steel alloys and minimum radii on wetted parts for mixers in the food and beverage industries. Similarly, the ASME BPE-2019 specification for bioprocessing equipment dictates sealed sanitary industrial mixer requirements in the pharmaceutical and biomedical industries.

For whatever your industrial mixing needs are, INDCO provides unparalleled quality with unparalleled care. To talk to a customer service representative or work with one of our engineers, visit our contact page today or call us at 1-800-851-1049.