Search Results for dispersion blade

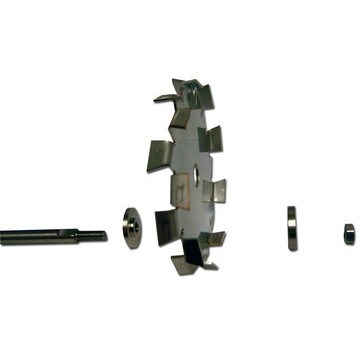

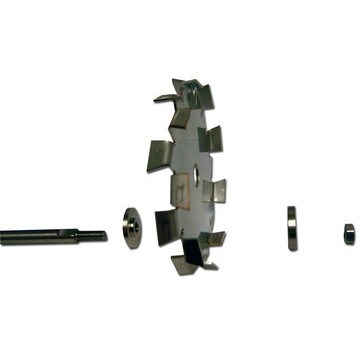

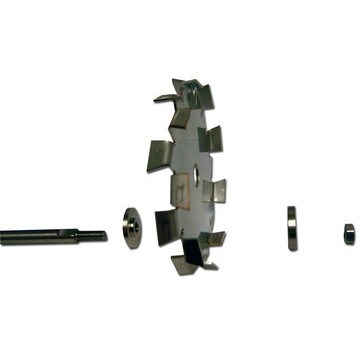

5/16" Dia. X 18" Long Dispersion Blade Adapter Shaft

SKU:TS526

5/16" Dia. X 18" Long Dispersion Blade Adapter Shaft

3/8" Dia. X 18" Long Dispersion Blade Adapter Shaft

SKU:TS138

3/8" Dia. X 18" Long Dispersion Blade Adapter Shaft

5/8" Center Hole to 7/8" shaft Dispersion Blade Adapter

SKU:HS504

5/8" Center Hole to 7/8" shaft Dispersion Blade Adapter, DISPERSER BLADE ADAPTER (5/8"-7/8") Model # HS504

3/8" Dia. X 12" Long Dispersion Blade Adapter Shaft

SKU:TS038

3/8" Dia. X 12" Long Dispersion Blade Adapter Shaft

1/2" Center Hole to 3/8" shaft Dispersion Blade Adapter

SKU:HS500

1/2" Center Hole to 3/8" shaft Dispersion Blade Adapter, DISPERSER BLADE ADAPTER (1/2"-3/8") Model # HS500

30" Dia. X 5/8" Center Hole Type D 304 SS Dispersion Blade - Coated

SKU:DB30DT

30" Dia. X 5/8" Center Hole Type D 304 SS Dispersion Blade - Coated, DISPERSOPM BLADE Design D 30" Standard Center Hole: 5/8" TC Coated Model # DB30DT

The Fundamentals of Dispersion in Mixing

The Fundamentals of Dispersion in Mixing, will be greater. In this case, the fan blades are similar to the teeth around the edge of a dispersion blade, a variety of dispersion blades and disperser equipment. Understanding the key concepts surrounding dispersion is crucial before ordering your high-speed disperser blade or dispersion blade. What is a Dispersion Blade?A dispersion blade is a key component in the process of dispersion. It is designed to break apart particles when it rotates at high speeds, facilitating the dispersion process. The blade

How Dispersion Works

How Dispersion Works, High shear dispersion works when particles contact a rotating dispersion blade and are broken apart. The process requires equipment with high RPM and HP in order for the dispersion blade to reach tip, or download the pdf version of this post. How Dispersion Works: Steps 1. Dispersion blade turns 2. Particles contact the blade and are broken apart a. The process of dispersion is a high-speed, the dispersion blades should run at tip speeds of 2,500 to 5,000 feet per minute. Your precise speed can

INDCO Fundamentals of Dispersion

INDCO Fundamentals of Dispersion, manufactures a variety of dispersion blades and disperser equipment designs. Some key concepts surrounding dispersion are important to understand before ordering your dispersion blade or disperser, to the top surface of the blade is desirable. As the dispersion blade turns, particles contact the blade, not be less than that below the blade. Round vessels almost always provide better dispersion than, , and D blades will vary the most in their pumping action rather than their shearing ability. A blade's

4 Preventive Maintenance Tips for Dispersers

of a homogeneous liquid product results from the high shear action of the blade. Dispersion blades, : The dispersion blade turns. Particles make contact with the blade within the vessel and are broken, At INDCO, we offer a full line of dispersion equipment from fractional-horsepower benchtops, dispersion, construction and more. Our dispersers are built for reliability and longevity, is a disperser? How does it work?”, you’re in luck. Dispersion is a high-speed, high-shear process requiring

May 2013 Top Sellers are Mixing Propellers

, hydrofoils, folding impellers, axial and radial flow turbines and dispersion blades are all

Mixing Impeller Selection: Which Design is Best?

mentioned designs, the hydrofoil provides the gentlest agitation with the least shear. Its blade, by welding blades formed from flat plates to a cylindrical hub. The marine style propeller performs, to hydrofoils but with large, flat blade surfaces at 45-degree angles to contact and therefore push more viscous materials. Primarily used for flow-controlled processes with higher viscosities, the blade, . In order to achieve this motion flat blades are welded to the hub like the axial flow turbine

How to Operate an Electric High-Speed Disperser Mixer: A Basic Guide

How to Assemble Dispersion Blades How to Calculate Tip Speed for a Dispersion Blade, . Safety Note: Never operate a high-speed dispersion blade in open air. The liquid in the vessel, medium in the vessel. Ensure the impeller is fully submerged. The dispersion blade should, The dispersion process works by bringing the blade to a high rate of speed in the base liquid medium, style propeller and dispersion is that the dispersion process is shear-driven. The action from

Industrial Mixing Applications: Understanding the Difference between High Shear and Low Shear

the appropriate mixing impeller or high shear dispersion blade design and the rotational speed of the mixer, to as dispersion, is characterized by the use of sawtooth type flat blades turning at high, shear dispersion, a minimum blade tip speed of 2500 feet per minute is commonly recommended. The tip, a dispersion blade on an undersized direct drive mixer motor resulting in overheating and potential, , dispersion or homogenization application. All mixing process equipment generates flow and shear

Variable Speed Air Stirrers - September 2017

and gear drive 1/3-4 HP, mixing shaft, propeller or dispersion blade and a block clamp and stand. We, , shaft and prop or dispersion blade. Click to shop all stirrer packages, Shop Support Stands DB3A Shop Blades

Am I Mixing or Dispersing? What’s the Difference?

that is commonly misunderstood is that for true dispersion a high tip speed at the end of the blade is critical, . Simply putting a dispersion blade on a mixer designed for blending does not provide the results, calls for a mixer or a disperser. Mixing and dispersion processes both entail rotating equipment, definitions, discussion of flow vs. shear, mixing and dispersion equipment differences and examples of each, mixing (also referred to as blending) and dispersion processes technically meet that definition

Technical Information - Product Videos | INDCO

-Clamp, Bracket Mount Mixer HOW TO INSTALL A CLAMP MOUNT MIXER How to Measure and Specify Dispersion Blade Hole Patterns How to Assemble Dispersion Blades How to Install a Hydrofoil Impeller How, Turbine MIxes in Water How to Measure and Specify Dispersion Blade Hole Patterns Introduction to INDCO's Impellers How to Assemble Dispersion Blades How to Install a Hydrofoil Impeller How

The Difference Between High Shear and Low Shear Mixing

of a sharp-edged blade is desirable. As the dispersion blade turns, particles contact the blade, of encountering a mixing blade or impeller. The amount of shear is dictated by the blade design, Mixer The hydrofoil provides the gentlest agitation with the least shear. Its blade profile creates, as well. Axial flow turbines are fabricated similarly to hydrofoils but with large, flat blade surfaces, -controlled processes with higher viscosities, the blade edges provide higher shear and require

Commercial Paint Mixer Solutions

, as they work on a very small scale using dispersion blades to thoroughly mix the intended product, blending. The use of dispersion blades will support high-shear mixing, and a bow-tie style impeller can, dispersion or high-viscosity blending. A simple changeover and change of impellers easily allows

Frequently Asked Questions - Get Answers Here! | INDCO

and a dispersion blade is almost completely converted to shear. All of our mixers are outfitted, into shear. A three-blade propeller will convert most of the energy to product motion, but a higher percent, , like gas dispersion, where the product must be forced against the walls of the vessel. Dispersion blades are used when solids must be imparted into liquids aggressively. If you need assistance when, blades. Baffles are especially needed with top-side entry mixers. Question: How do I obtain material